High Strength Anchor Bolt

If you have any requirements for the product, you can contact us immediately

SPECIFICATIONS

| Range of working temperature | -40℃~50℃ |

| Material | 42CrMoA、35CrMoA |

| Product level | Class 8.8, Class 10.9, Class 12.9 |

| Product specifications | M36、M39、M42、M48、M56 |

| length | 2m~12m |

| Executive standard | GB/T3098.1 or acc. to customer technical requirements |

PERFORMANCE ADVANTAGE

High Strength Anchor Bolt

Wind turbine anchor bolt raw material is 42CrMoA and other equivalent materials. It is purchased from large and qualified steel mills. Each steel round bar went through ultrasonic flaw detection before delivery. According to GB/T 4162 standard, reaches Class A level. LongTeng guarantee high strength anchor bolts supplied can meet or even higher than the technical specifications required in bidding documents.

High Strength Anchor Bolt

Wind turbine anchor bolt raw material is 42CrMoA and other equivalent materials. It is purchased from large and qualified steel mills. Each steel round bar went through ultrasonic flaw detection before delivery. According to GB/T 4162 standard, reaches Class A level. LongTeng guarantee high strength anchor bolts supplied can meet or even higher than the technical specifications required in bidding documents.

Our high strength anchor bolts for wind turbine are manufactured following strict standard production process: anchor bolt is heat treated and then threaded: anchor bolt is tested after heat treatment, then peeled and drawing is processed to the specified medium diameter size. Peeling process can remove oxide scale and decarburization layer generated during heat treatment; and the last is screw thread.

Note: The middle part of wind turbine anchor bolt is not machined, it is one-time forming and thread precision is better.

Note: The middle part of wind turbine anchor bolt is not machined, it is one-time forming and thread precision is better.

High-Trenght Wind Turbine Anchor Bolt Product Process:

Production Process Flow

Purchase raw materials according to plan (designated steel mill materials and grades) → Raw material Inspection → rough straightening → heat treatment (medium frequency induction heat treatment) → inspection (performance test) → peeling and fine alignment (100% ultrasonic flaw detection, fluorescent magnetic particle inspection, etc.) →Unloading→Machining (Chamfering)→Coded→Thread Rolling→Inspection (Threading Precision Gauge, Medium Diameter Micrometer, etc.)→ Anchor Bolt Tension Detection→ Anchor Bolt Anticorrosion Treatment (Dakro, coated according to customer requirements) Grease + heat shrinkable tube, etc.) → inspection → packaging → storage.

Inspection Equipment:

Anchor Bolt Test after Production:

Tensile Test: We make 100% tensile test to steel bars according to client’s request, tensile strength is 70% of the yield strength.(A bit higher than actual tensile strength).The elongation or re-condensation within ≤±0.02mm/m.

Anti-Corrosion Test: We use anti-corrosion grease+anti-corrosion belt +PVC tube+sealing nut to achieve the purpose. After 1000 hours’ salt spray test, there will be no corrosion on the products’ surface.

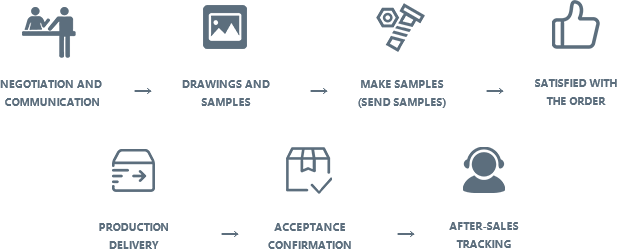

BOLT BUSINESS COOPERATION PROCESS

CLASSICS ALL OVER THE WORLD

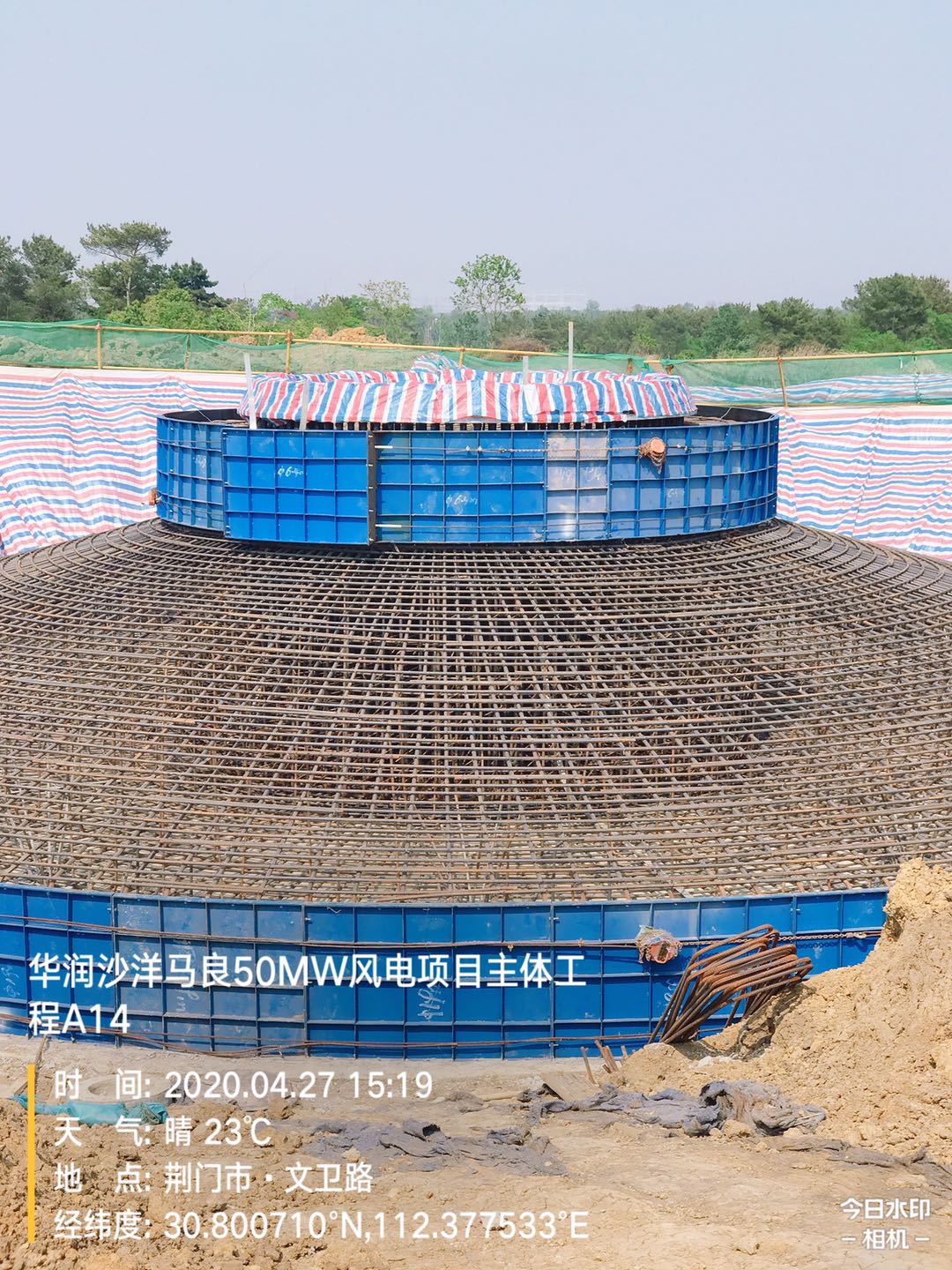

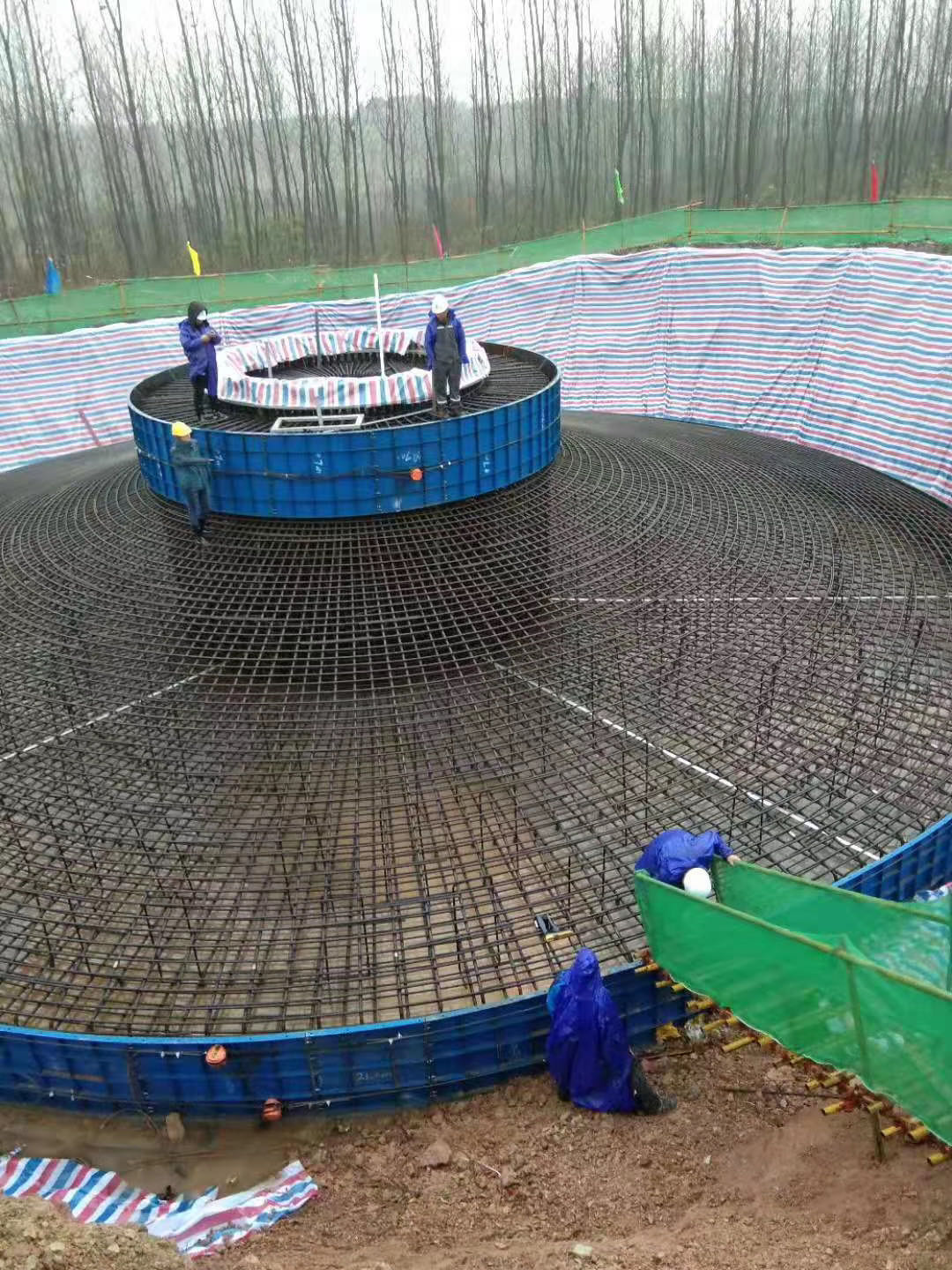

PROJECT CASES

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →