Double End Stud Bolt(42CrMoA, 40CrNiMoA)

If you have any requirements for the product, you can contact us immediately

SPECIFICATIONS

PERFORMANCE ADVANTAGE

High Strength Double End Stud

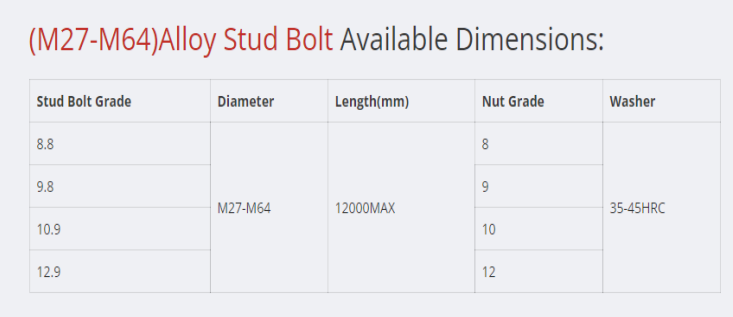

Stud Bolt Specification

Raw Material: 42CrMoA, 40CrNiMoA

Strength Level: 8.8, 10.9

Dimension: M27~M64

Length: 2m-12m

42CrMoA, 40CrNiMoA -Alloy Stud Bolt Types Introduction

Alloy Stud bolt (42CrMoA, 40CrNiMoA) has a thread on full lengths or at both ends. As shown in images. It is having three components if washers are not used (two nuts and stud). If you used washer it would become five. Sometimes additional nuts are used for hydraulic tensioning with larger size stud.

Alloy Double End studs are available in cut or rolled threads in any grade of material. They may be furnished plain, plated or coated at the customer’s request. LT Group provides heat-treatment, cold thread, lab services according to customer’s technical requirements.

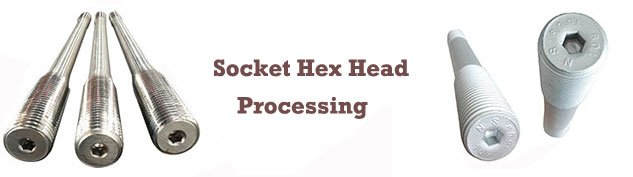

(M27-M64)Alloy Stud Socket Hex Head Processing:

Bolt Fasteners can provide socket hex head processing for Large size (M27-M64) stud bolt product for customers .

42CrMoA-Alloy Stud Bolt Surface Treatment:

Alloy Stud bolt Surface Treatment has many options, such as Oil, Grease, Dacromet, Zinc coating,Paint, tape, fabric, Water-proof Paper, Box. There are 2 most used treatment – zinc coating and Black Oxide Coating. Here are the outlooks:

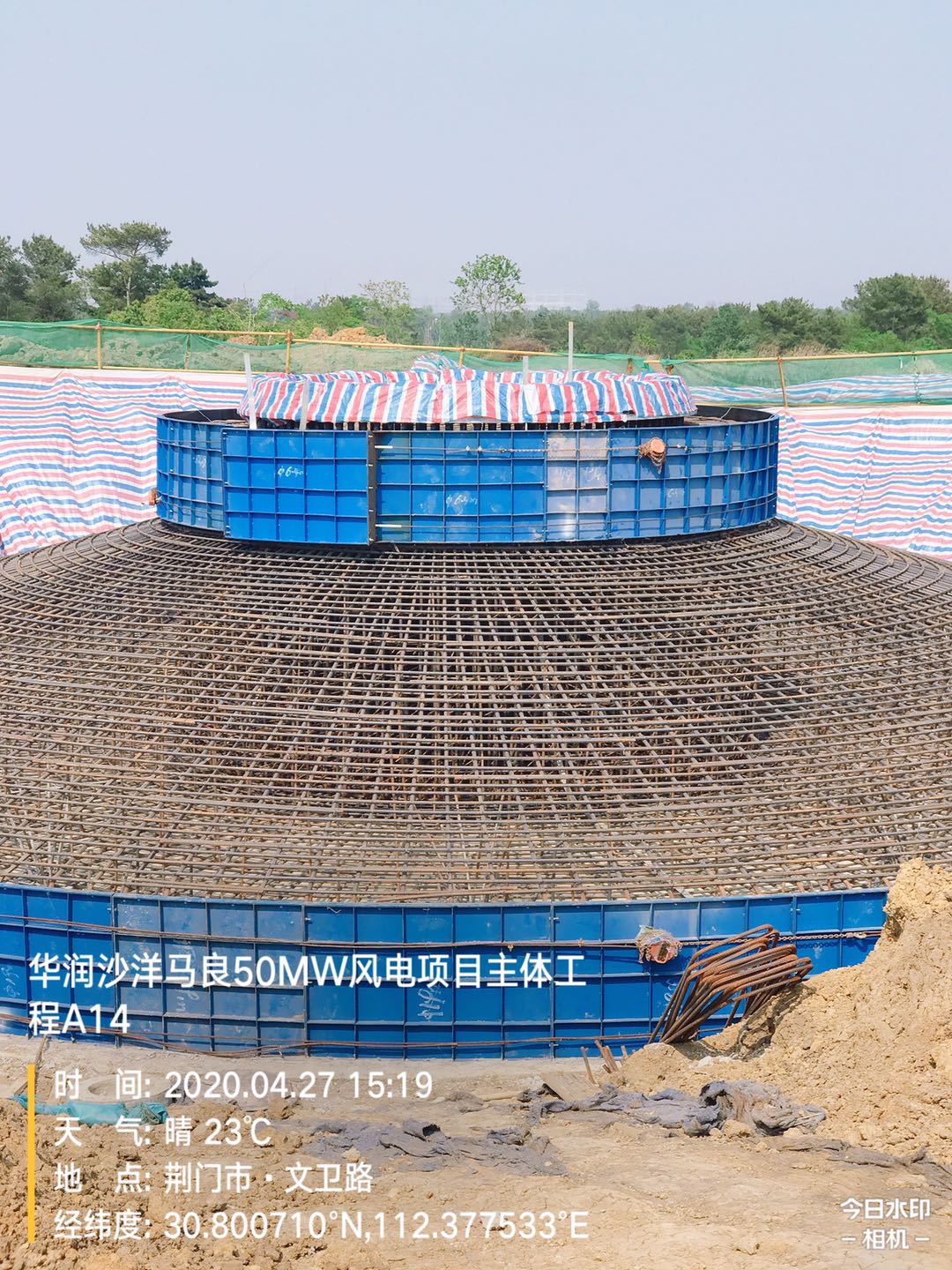

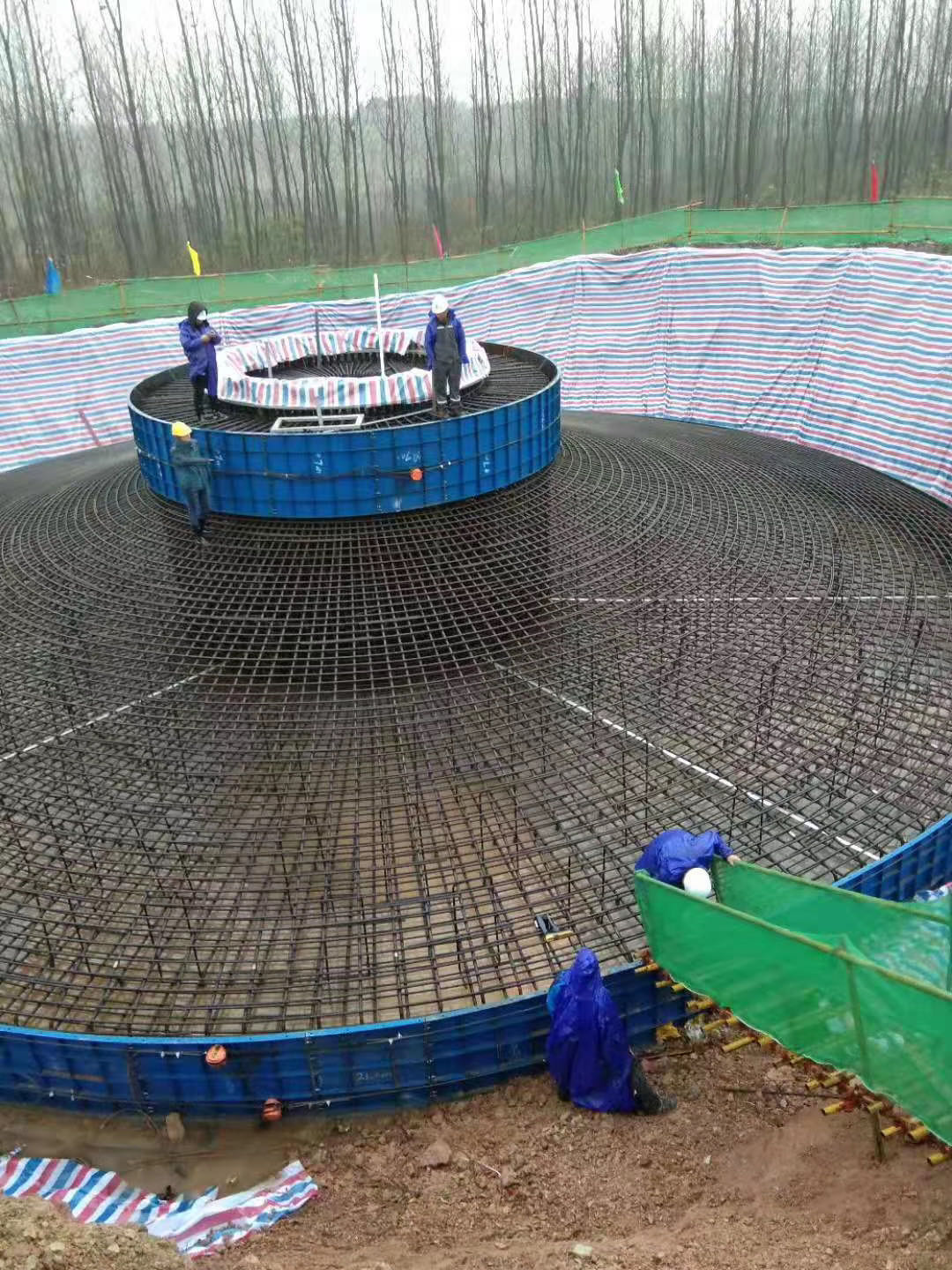

Alloy Stud Bolt (M27-M64) Application

Large size (M27-M64) Alloy Stud bolt is a threaded rod with 2 heavy hexagon nuts, it is a component developed for flange connections in Petrochemical and Oil & Gas industry, now its been used in many more fields. Wind tower, Nuclear power, Railway, Automotive industry, Railway, Construction, Electronic industry.

Large size stud bolt (M27-M64) with different thread forms has been developed for various applications, and the major difference is the threading method and thread length.

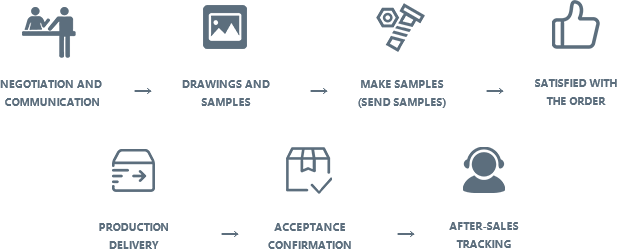

BOLT BUSINESS COOPERATION PROCESS

CLASSICS ALL OVER THE WORLD

PROJECT CASES

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →