Wind Blade Bolt

If you have any requirements for the product, you can contact us immediately

SPECIFICATIONS

PERFORMANCE ADVANTAGE

Blade bolt is one type of wind power fasteners, it is used for the connection of blade and wind wheel hub. Longteng supplies stud bolt manufactured according to GB901, and most of the yield strength grade of wind blade bolt is 10.9, Longteng can provide stud bolt yield strength up to 12.9 grade.

Socket Hex Head Processing

Longteng can provide socket hex head processing for wind blade root bolt product for customers.

How is Wind Blade Bolted to Wind Wheel Hub

Wind power blade bolt structure is a wind vane bolt embedded forming structure, it mainly includes joint of wind blade and the wind wheel hub, its features are: there are many bolt set be evenly on the blade root is relatively fixed, embedded in the middle of the glass fiber increase of blade root structure parts, and embedded bolt set is outer wrapped with a fiberglass roving unilateral, the coupling part structure and the wind blade shape together, after being molded, the connection structure and the wind blade forms a connection group. The embedded bolt sleeve structure makes the connection between blade and hub reliably. This structure design can avoid harm to the blade root structure layer, and bearing capacity of wind blade root structure is controlled at a reasonable level.

A molded structure embedded in the bolt sleeve of a wind turbine blade comprises a connection between the blade and the hub of a wind turbine. It is characterized by a plurality of bolts near the middle position of the fiberglass reinforced structure at the blade root.

The sleeve is uniformly embedded and fixed at the corresponding position at the root of the blade, and the embedded blade bolt of the sleeve is wrapped with glass fiber unidirectional fiber, and the space between the bolt sleeves is embedded with wedge-shaped strips. This connection structure is joined together with the rest of the blade.

After the wind turbine blade is installed, the connecting structure and wind blade work together as a whole section. A reliable connection between wind blades and the hub can be achieved through the embedded bolt sleeve structure. When machining the blade root structure layer, this structure can avoid the damage, and wind blade root structure is subjected to reasonable stress. The positioning tool ensures the position and angle of blade bolts. The positioning tool is more accurate and ensures the impeller is installed correctly.

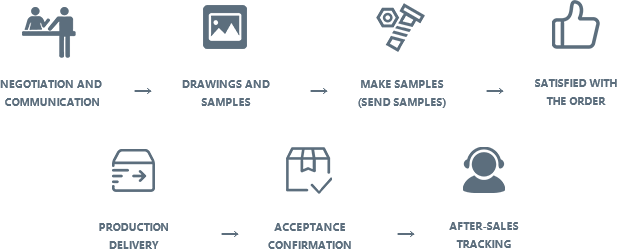

BOLT BUSINESS COOPERATION PROCESS

CLASSICS ALL OVER THE WORLD

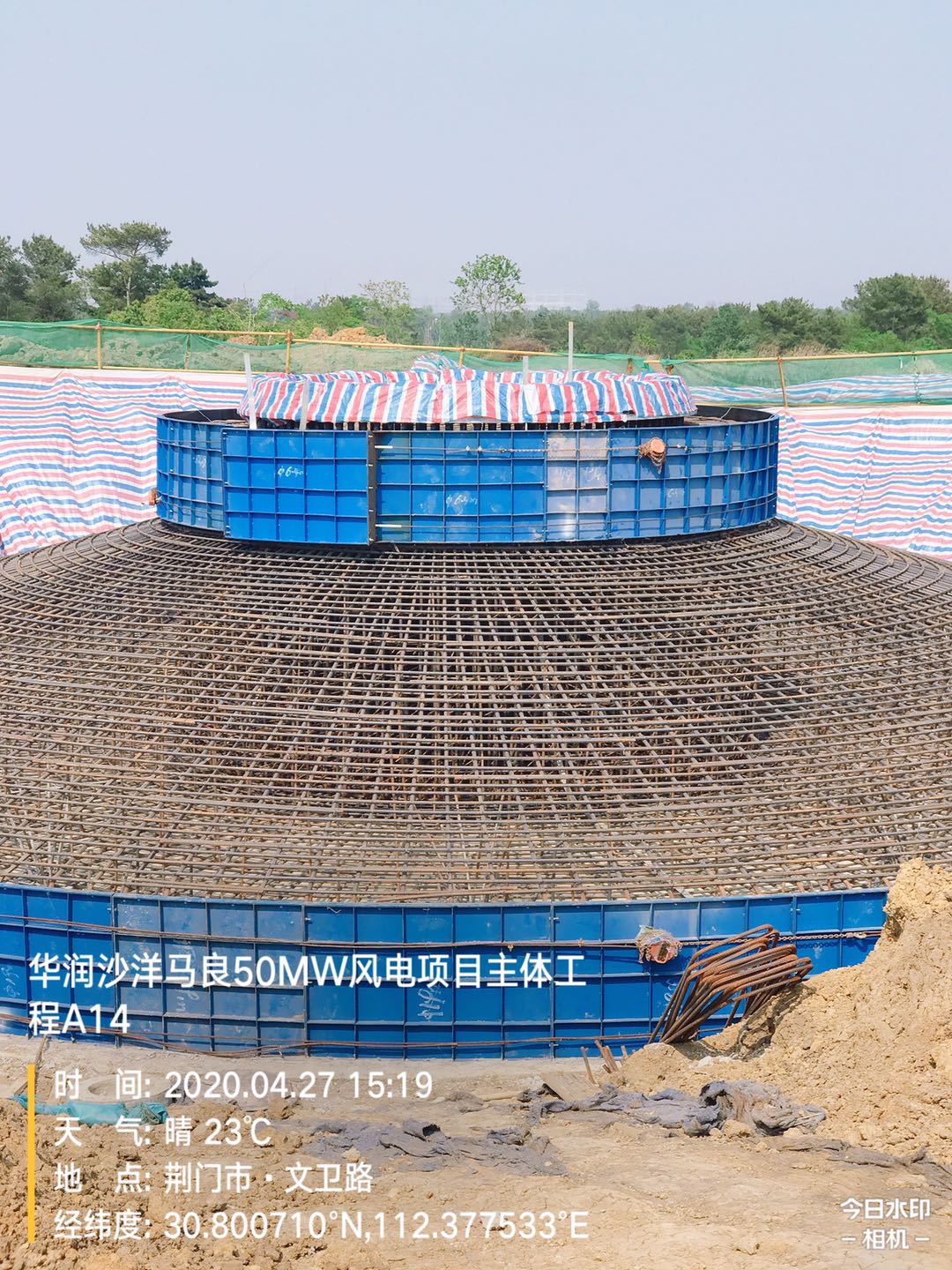

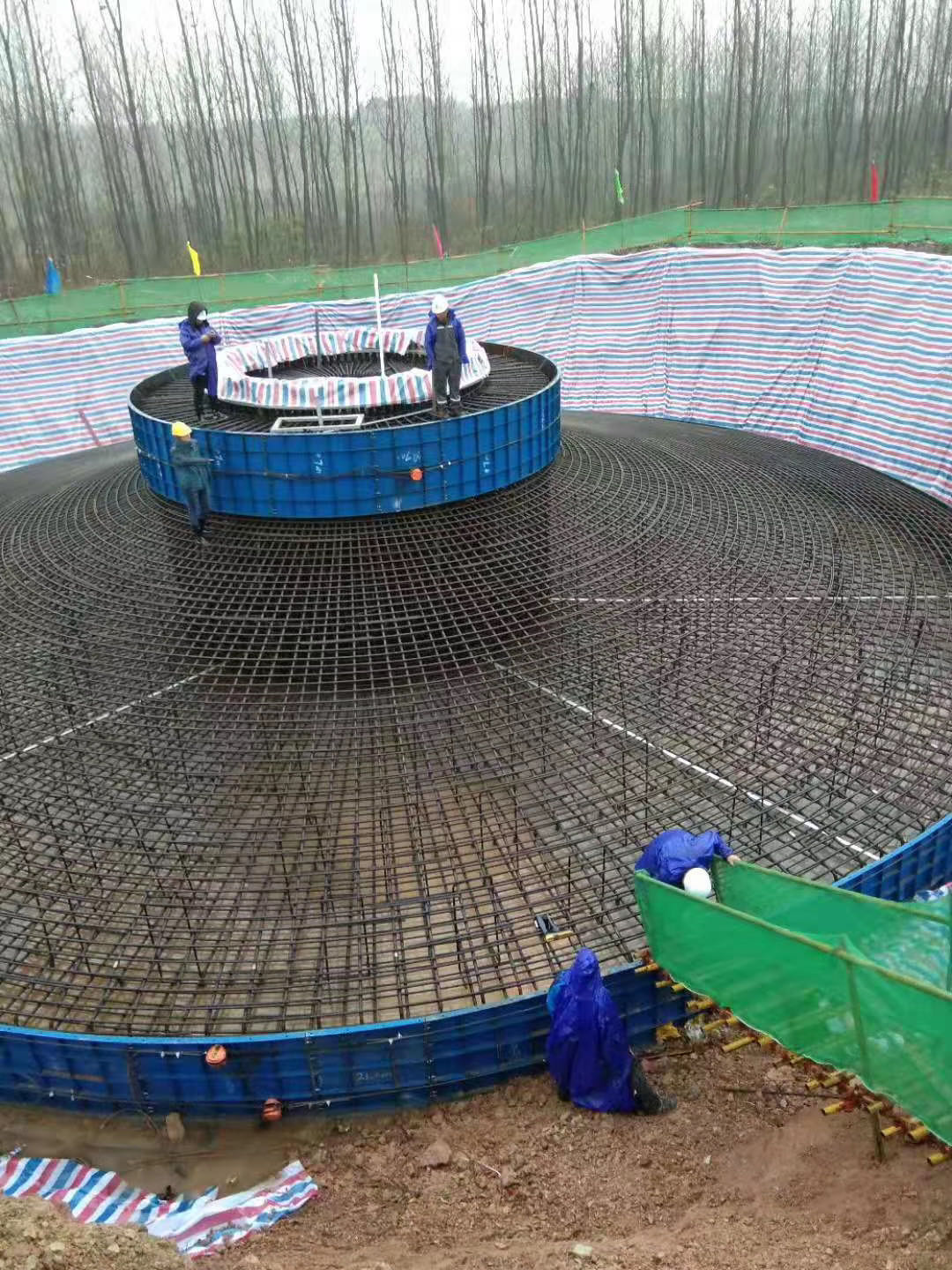

PROJECT CASES

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →