Round Bar Grinding

If you have any requirements for the product, you can contact us immediately

SPECIFICATIONS

PERFORMANCE ADVANTAGE

Grinding is such a significant process which gives final judgment to the tolerance, straightness, and precision of a round bar. This takes a thoroughly abrasive method of biting and cutting away unwanted bar parts from the material to improve the outer surface, finish and mill to the middle diameter, to ensure straightness, surface roughness and other requirements in line with the drawings.

There are lots of reasons for the round bar needs grinding, mainly contains, accurate tolerance needed, precise straightness, finished smooth surface and abrasive material removal.

Grinding methods have become popular and useful to most operators because they can perform all the necessary work under one roof – during fast delivery times. Rapid material removal enables high-precision work and brings out the physical properties required for steel bars.

Grinding steel can be done in a variety of ways, depending on the type of workpiece that requires specific tolerances, cuts and diameters.

BOLT BUSINESS COOPERATION PROCESS

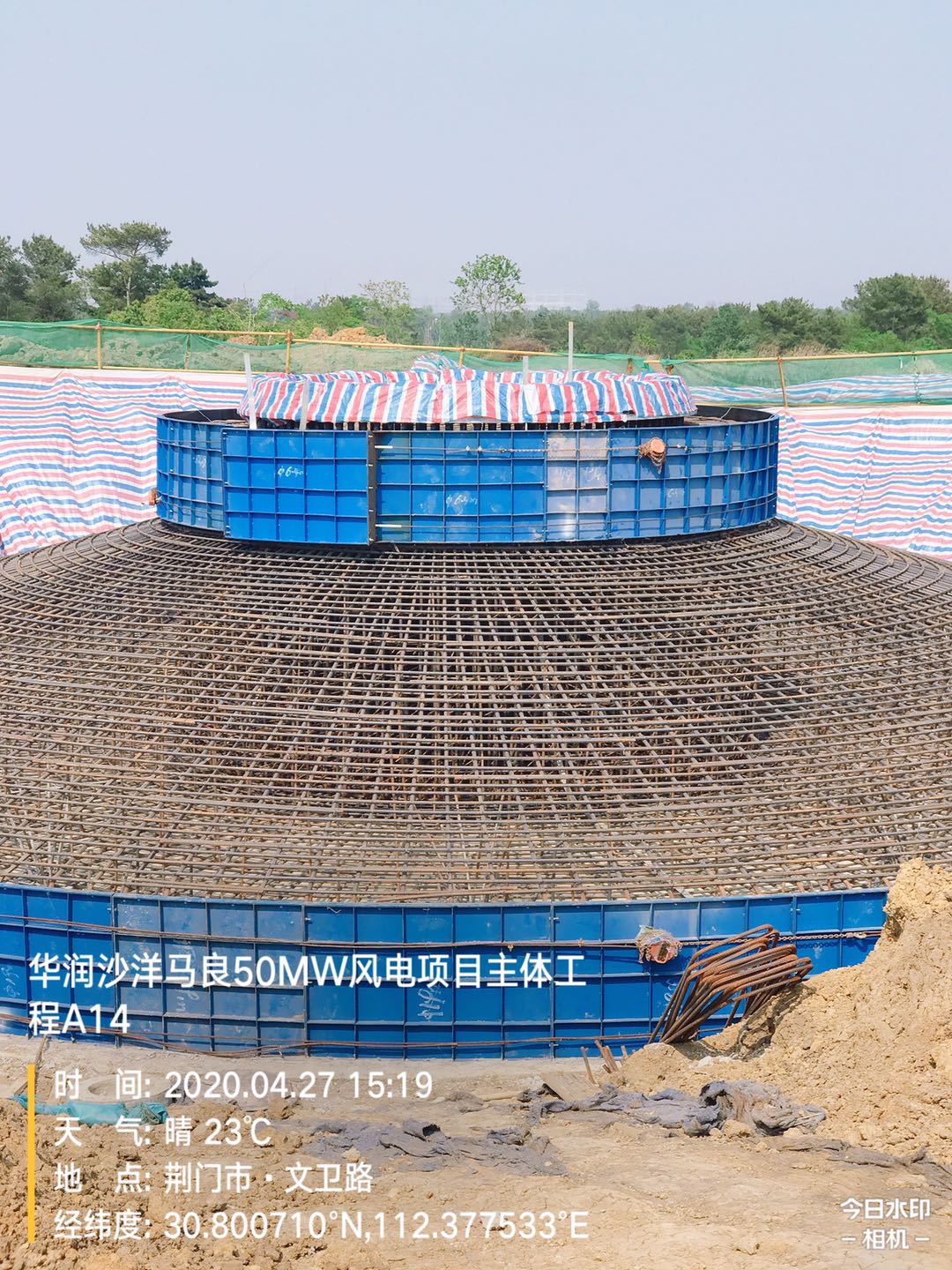

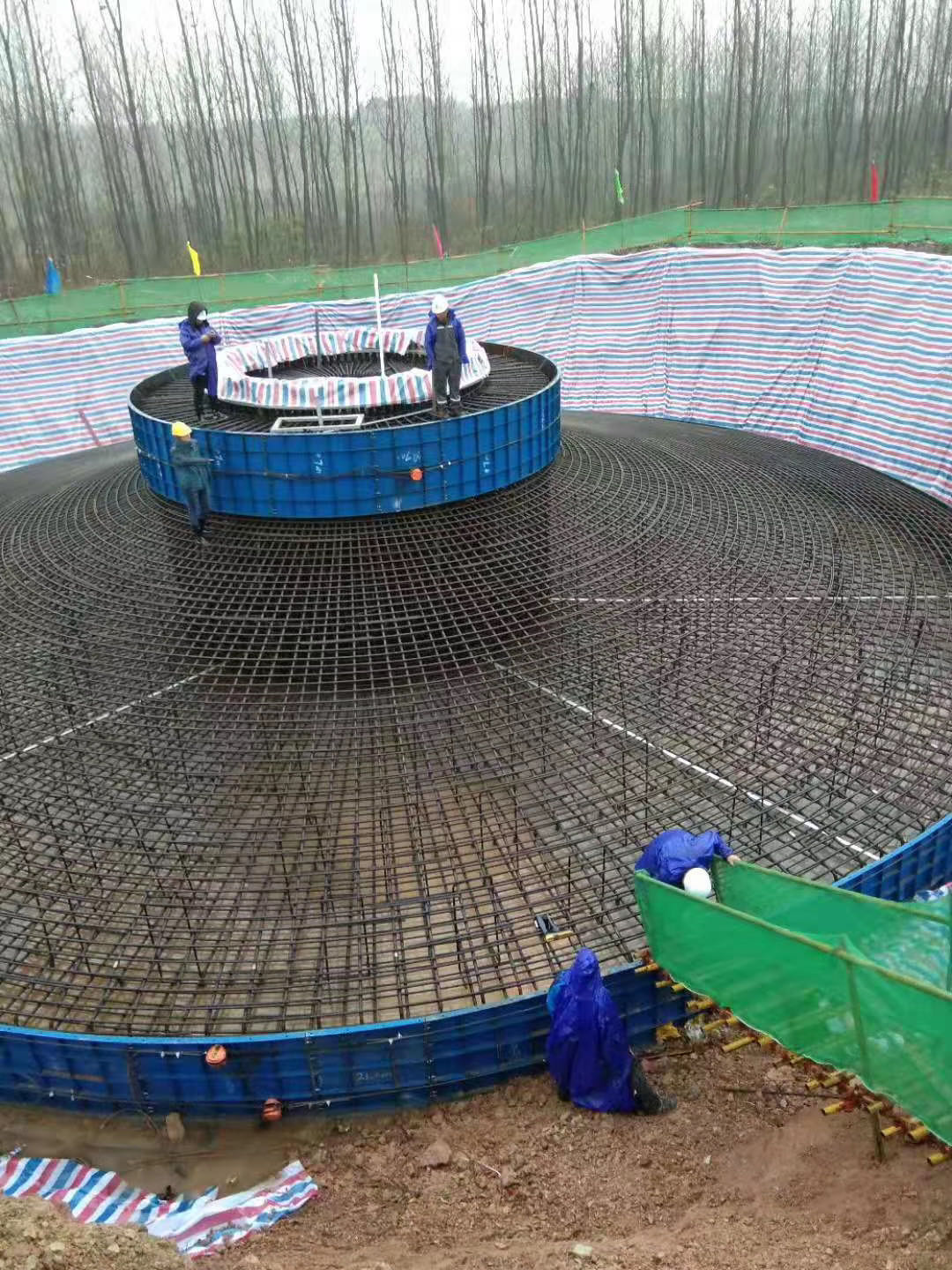

CLASSICS ALL OVER THE WORLD

PROJECT CASES

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →