Provide customers with high performance products

All products: High strength stud ( WTG foundation bolt WTG blade bolt Full thread stud Marine stud bolt Bridge stud bolt Rock breaker though stud bolt ) Hex head bolt Anchor plate assembly WTG blade bushing OEM fabrication ( Heat-treated round bar Grinted steel rod Cold rolled thread Turning lathe ) Rock bolt assembly

High strength stud WTG foundation bolt WTG blade bolt Full thread stud Marine stud bolt Bridge stud bolt Rock breaker though stud bolt

-

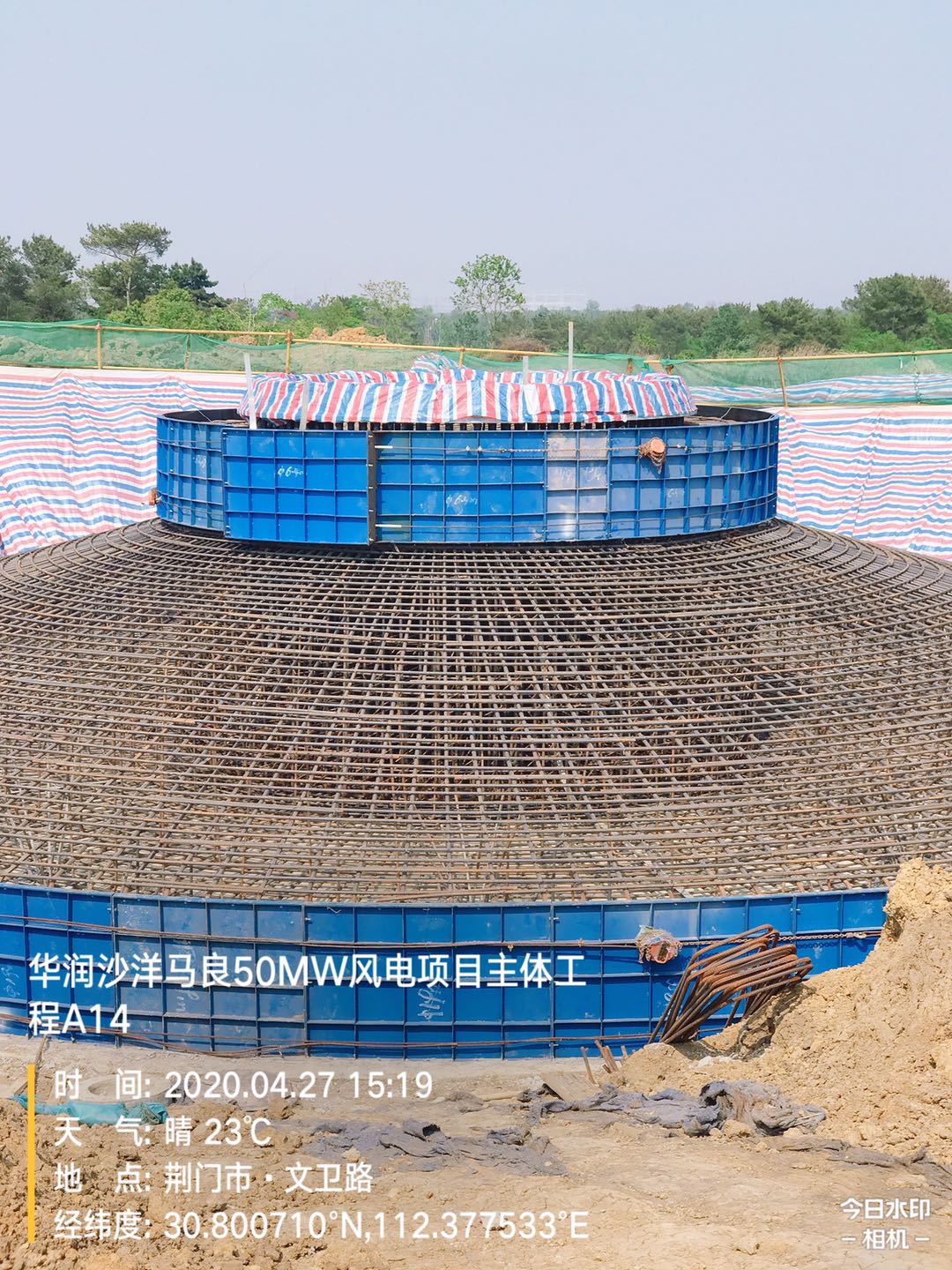

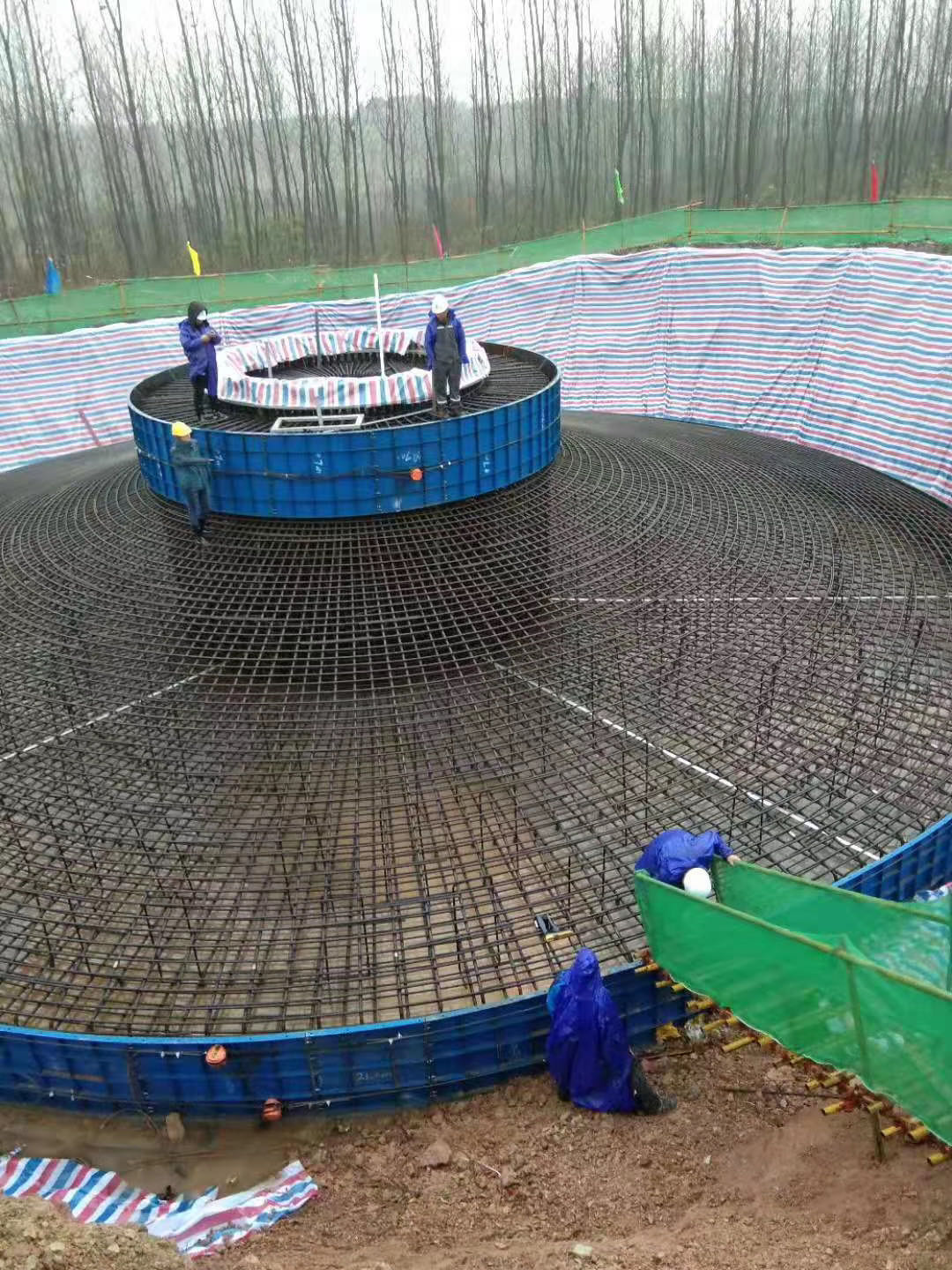

WIND TURBINE FOUNDATION ANCHOR BOLT CAGE ASSEMBLY

It is applicable to anchor bolt components for the foundation of onshore and offshore wind turbines.

Range of working temperature: -40℃~50℃ Material: 42CrMoA、35CrMoA Product level: Class 8.8, Class 10.9, Class 12.9 Product specifications: M36、M39、M42、M48、M56 length: 2m~12m Executive standard: GB/T3098.1 or acc. to customer technical requirements -

WIND TURBINE BLADE BOLT

It is used for the connecting pair between wind turbine and wind blade.

Material: 42CrMoA, 35CrMoA Product level: 8.8, 10.9 Product specification: M36, M39, M42, M48, M56 Executive standard: GB / t901 or according to customer requirements -

STUD BOLT WITH ALL THREAD OR HALF THREAD

The connecting pair is used for steel structure plants, venues, wind towers, etc

Material: 42CrMoA, 35CrMoA, 40CrNiMoA Product level: 8.8, 10.9 Product specification: M18 ~ M64 length: 2m ~ 12m Executive standard: GB / t3098 one -

FULLY THREADED ROD

The whole support rod body is through thread

Material: 42CrMoA、35CrMoA、40CrNiMoA Product level: Class 8.8, Class 10.9 Product specifications: M18~M64 Length: No more than 12m Executive standard: GB/T3098.1、GB/T197、GB/T196 -

post tension bar systems, PT bolt

The whole rod body is through thread

Diameters: M64 M56 M48 M42 M39 M36, customers' technical requirements Length: 1~11.8 meters Property Class: 8.8 9.8 10.9 12.9 Accessories: Nut, plain washer, dome/spherical nut, dome/spherical washer, coupler Thread: cut thread, rolled thread Thread length: Acc. to customers' technical requirements Thread tolerance: ISO 965-1, 6g Rod standard: ISO 898 NDT inspection: 99.99% megnectic partical test, 99.99% ultrasonic test Inspection document: EN 10204 type 3.1, type 3.2 -

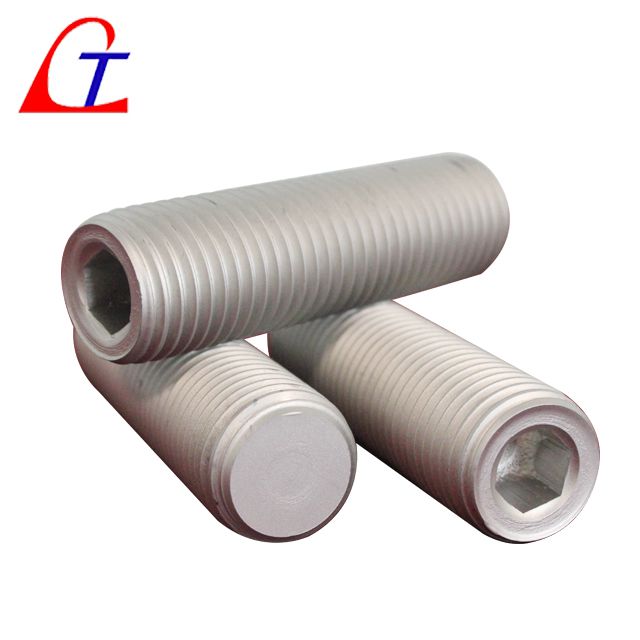

Marine Stud bolt

Application: Large stud bolt for shipbuilding with high strength Standard: clients’ requirements, OEM acceptable Material: 42CrMoA、40CrNiMo Property class: 8.8、10.9、12.9 Specification: M27-M64 Length: 100-900mm Coating: oil、black、dacromet 、zinc spray Advantage: High product performance, Impact energy up to 60J, high precision in dimension; Inner hex provided -

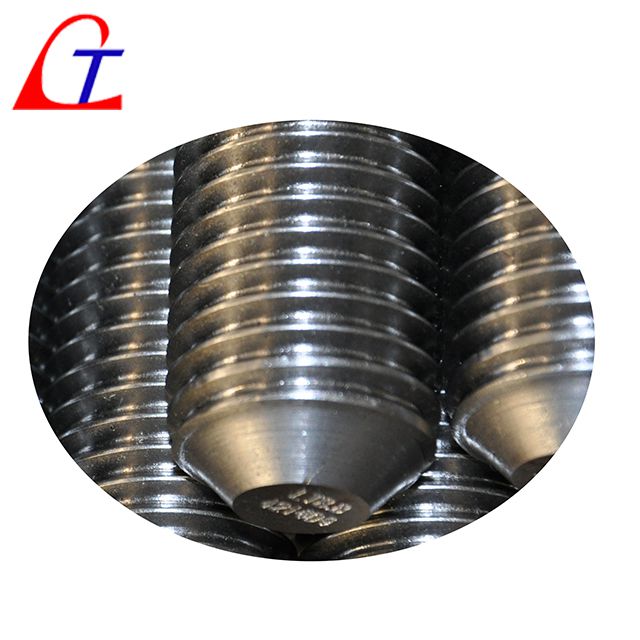

THROUGH BOLT STUD FOR ROCK BREAKER

Application: hydraulic rock breaker Standard: clients’ requirements Material: 42CrMoA、40Cr Property class: 8.8、10.9、12.9 Specification: M27-M64 Length: 100-4000mm Coating: oil、black、dacromet 、zinc spray Advantage: High performance, factory standards much higher than customers’ requirements -

Hexagon socket bolt

Hexagon socket bolt is a hexagon bolt with a recess in the middle. It is mainly used in electrical a

Material: 42CrMoA, 35CrMoA, 40Cr, 45# Product level: 8.8, 10.9, 12.9 Product specifications: M24, M27, M30, M33, M36, M39, M42, M48, M56, M64 Executive Standards: GB / T70, GB / T77, GB / T78, GB / t79, GB / T80 or according to customer requirements -

High Strength Anchor Bolt

Range of working temperature: -40℃~50℃ Material: 42CrMoA、35CrMoA Product level: Class 8.8, Class 10.9, Class 12.9 Product specifications: M36、M39、M42、M48、M56 length: 2m~12m Executive standard: GB/T3098.1 or acc. to customer technical requirements -

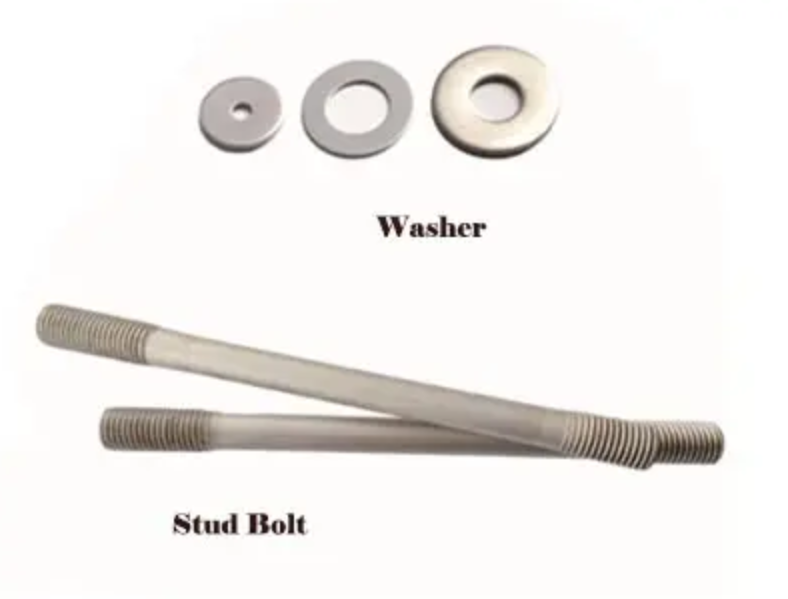

Double End Stud Bolt(42CrMoA, 40CrNiMoA)

High Strength Double End StudStud Bolt SpecificationRaw Material: 42CrMoA, 40CrNiMoAStrength Level: 8.8, 10.9Dimension: M27~M64Length: 2m-12m42CrMoA, 40CrNiMoA -Alloy Stud Bolt Types IntroductionAlloy Stud bolt (42CrMoA, 40CrNiMoA) has a thread on full lengths or at both ends. As shown in images. It is having three components if washers are not used (two nuts and stud). If you used washer it would become five. Sometimes additional nuts are used for hydraulic tensioning with larger size stud.Alloy Double End studs are available in cut or rolled threads in any grade of material. They may be furnished plain, plated or coated at the customer’s request. LT Group provides heat-treatment, cold thread, lab services according to customer’s technical requirements.(M27-M64)Alloy Stud Socket Hex Head Processing:Bolt Fasteners can provide socket hex head processing for Large size (M27-M64) stud bolt product for customers .42CrMoA-Alloy Stud Bolt Surface Treatment:Alloy Stud bolt Surface Treatment has many options, such as Oil, Grease, Dacromet, Zinc coating,Paint, tape, fabric, Water-proof Paper, Box. There are 2 most used treatment – zinc coating and Black Oxide Coating. Here are the outlooks:Alloy Stud Bolt (M27-M64) ApplicationLarge size (M27-M64) Alloy Stud bolt is a threaded rod with 2 heavy hexagon nuts, it is a component developed for flange connections in Petrochemical and Oil & Gas industry, now its been used in many more fields. Wind tower, Nuclear power, Railway, Automotive industry, Railway, Construction, Electronic industry.Large size stud bolt (M27-M64) with different thread forms has been developed for various applications, and the major difference is the threading method and thread length.

-

High Strength Anchor Bolt

High Strength Anchor BoltWind turbine anchor bolt raw material is 42CrMoA and other equivalent materials. It is purchased from large and qualified steel mills. Each steel round bar went through ultrasonic flaw detection before delivery. According to GB/T 4162 standard, reaches Class A level. LongTeng guarantee high strength anchor bolts supplied can meet or even higher than the technical specifications required in bidding documents.Our high strength anchor bolts for wind turbine are manufactured following strict standard production process: anchor bolt is heat treated and then threaded: anchor bolt is tested after heat treatment, then peeled and drawing is processed to the specified medium diameter size. Peeling process can remove oxide scale and decarburization layer generated during heat treatment; and the last is screw thread.Note: The middle part of wind turbine anchor bolt is not machined, it is one-time forming and thread precision is better.High-Trenght Wind Turbine Anchor Bolt Product Process:Production Process FlowPurchase raw materials according to plan (designated steel mill materials and grades) → Raw material Inspection → rough straightening → heat treatment (medium frequency induction heat treatment) → inspection (performance test) → peeling and fine alignment (100% ultrasonic flaw detection, fluorescent magnetic particle inspection, etc.) →Unloading→Machining (Chamfering)→Coded→Thread Rolling→Inspection (Threading Precision Gauge, Medium Diameter Micrometer, etc.)→ Anchor Bolt Tension Detection→ Anchor Bolt Anticorrosion Treatment (Dakro, coated according to customer requirements) Grease + heat shrinkable tube, etc.) → inspection → packaging → storage.Inspection Equipment:Anchor Bolt Test after Production:Tensile Test: We make 100% tensile test to steel bars according to client’s request, tensile strength is 70% of the yield strength.(A bit higher than actual tensile strength).The elongation or re-condensation within ≤±0.02mm/m.Anti-Corrosion Test: We use anti-corrosion grease+anti-corrosion belt +PVC tube+sealing nut to achieve the purpose. After 1000 hours’ salt spray test, there will be no corrosion on the products’ surface.

-

Nonstandard Stud Bolt

High strength large size nonstandard bolt strength grade: 8.8, 10.9, 12.9. It is mainly used in machinery and equipment, high-speed railway, construction steel structure, ships, bridges, roads, wind power generation, oil pipelines and other fields.Through Stud Bolt For Rock BreakerBolt Fasteners manufactures nonstandard stud bolt for hydraulic rock breaker, named as through bolt stud, featured with high stud bolt strength options 8.8, 10.9, 12.9, etc, we can produce according to customer requirements on other sizes due to the drawing provided.How to Order Nonstandard Stud Bolt from Bolt FastenersCustomized Dimension Drawing of Nonstandard Stud BoltDimensional drawing of stud bolt is essential for making nonstandard studs. The drawing can be provided by the customer, or customized and modified according to the customer’s requirements. Generally, we will send stud bolt samples for the customer to check.Steel Material of Nonstandard Stud BoltNonstandard stud bolts are generally made of 42CrMo, 40CrNiMoA, 35CrMo, 20MnTiB or others. If customers have other requirements, then select materials according to customers’ requirements. If customers do not have clear requirements, Bolt Fasteners will analyze the use environment and use and then select materials.Anti-Rust Surface Treatment of Nonstandard Stud BoltSize diagram and material of stud bolt can be made according to customer requirements, but for surface treatment, sometimes customer requirements cannot be met, Bolt Fasteners will give professional advice on whether the surface treatment is suitable for the material and customer requirements of the final product characteristics.

-

Wind Blade Bolt

Blade bolt is one type of wind power fasteners, it is used for the connection of blade and wind wheel hub. Longteng supplies stud bolt manufactured according to GB901, and most of the yield strength grade of wind blade bolt is 10.9, Longteng can provide stud bolt yield strength up to 12.9 grade.Socket Hex Head ProcessingLongteng can provide socket hex head processing for wind blade root bolt product for customers. How is Wind Blade Bolted to Wind Wheel HubWind power blade bolt structure is a wind vane bolt embedded forming structure, it mainly includes joint of wind blade and the wind wheel hub, its features are: there are many bolt set be evenly on the blade root is relatively fixed, embedded in the middle of the glass fiber increase of blade root structure parts, and embedded bolt set is outer wrapped with a fiberglass roving unilateral, the coupling part structure and the wind blade shape together, after being molded, the connection structure and the wind blade forms a connection group. The embedded bolt sleeve structure makes the connection between blade and hub reliably. This structure design can avoid harm to the blade root structure layer, and bearing capacity of wind blade root structure is controlled at a reasonable level. A molded structure embedded in the bolt sleeve of a wind turbine blade comprises a connection between the blade and the hub of a wind turbine. It is characterized by a plurality of bolts near the middle position of the fiberglass reinforced structure at the blade root.The sleeve is uniformly embedded and fixed at the corresponding position at the root of the blade, and the embedded blade bolt of the sleeve is wrapped with glass fiber unidirectional fiber, and the space between the bolt sleeves is embedded with wedge-shaped strips. This connection structure is joined together with the rest of the blade.After the wind turbine blade is installed, the connecting structure and wind blade work together as a whole section. A reliable connection between wind blades and the hub can be achieved through the embedded bolt sleeve structure. When machining the blade root structure layer, this structure can avoid the damage, and wind blade root structure is subjected to reasonable stress. The positioning tool ensures the position and angle of blade bolts. The positioning tool is more accurate and ensures the impeller is installed correctly.

-

Wind Tower Bolt

Wind Tower Bolt Supplied from Bolt FastenersWind tower bolt and nut plays a important role as joining components in fastening different parts of wind turbine tower, Longteng is a professional manufacturer which supplies high grades fasteners 8.8-12.9 for wind tower projects.Wind Tower Installation – Tower Bolts and FlangeWind tower shall be installed on concrete anchor cage foundation, and different part of wind tower are connected with tower bolts and flange. 2 wind turbine tower sections are jointed with high strength hex bolt and hot rolled steel flange, the bolting process shall be accurate, for less torque will make the fastening loose, and more torque will break the bolt and nut when bearing other forces, which lead to serious structural problems. Wind tower sections are bolted together inside the tower. The quality of the flanges and the bolt tensions are important parameters for the safety of wind turbine towers.

-

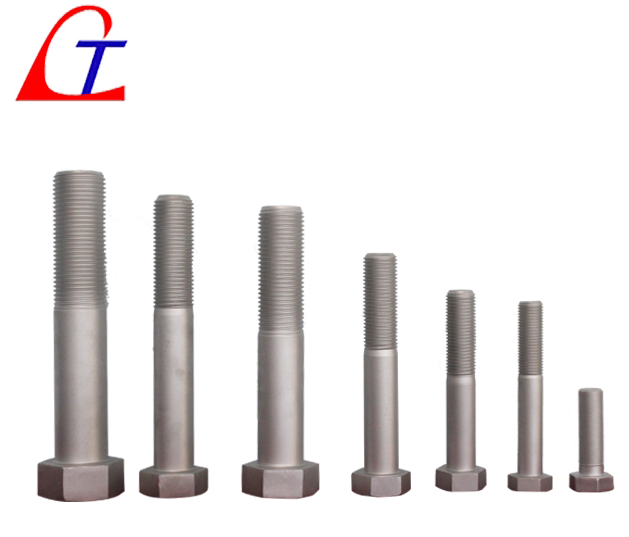

high tensile hexagon head bolts

A type of fastener consisting of head and screw (cylinder with external thread); For fastening two p

Material: 42CrMoA, 35CrMoA, 40Cr, 45# Product level: 8.8, 10.9, 12.9 Product specifications: M24, M27, M30, M33, M36, M39, M42, M48, M56, M64, M72 Executive Standards: GB/T5782、GB/T5783、EN14399Or according to customer requirements -

ISO 4014 hexagon head screws

Product: hexagon head screws / half thread Specification: M20-M72 Property Class: ISO898-1 8.8, 10.9 Thread tolerance: 6g,6e,6h Tolerance standard: ISO 4759-1 Quality management systems: ISO 4759-1 -

HEXAGON HEAD SCREW ISO 4017, CE, DOP, FULL THREAD

Product: hexagon head screws / full thread Specification: M20-M100 Property Class: ISO898-1 8.8, 10.9 Thread tolerance: 6g,6e,6h Tolerance standard: ISO 4759-1 Surface defect: ISO 6157-1 Quality management systems: ISO9001 -

DIN 933 hexagon bolt fully threaded

DIN933, bolt, hex bolt, hexagon bolt, hex head screw, big bolt, M42, m30, m36, m48, m56, m72, hex he

DIN933 is a bolt standarding for fully threaded hex bolt with thread diameter M1.6 ~M52, product grade: Grade A, Grade B. Grade A, d≤24mm, l ≤10d or l ≤150mm. Grade B: d >24mm or l >10d or 1>150mm. Value for s, e, k of grade A and Grade B are different.In common orders, hex bolt are M3-M64, with property class 8.8, 10.9, according to ISO 898-1.Thread tolerance and Coating: DIN933 hex bolt thread should be course thread or fine thread, dimension in mm. Tolerance for course thread is 6g. Coating methods are black oxide, electric galvanized, hot dip galvanized, etc. Thread tolerance before threading should be 6g/6H, tolerance after coating should be 6h/6g. Hex head bolt can be divided as full thread hex bolt DIN933 and half-thread hex bolt DIN931.DIN933 hexagon bolt is similar to ISO4017 and GB/T 5783.

-

EN15048 Non-preloaded structural bolting assemblies

Bolts grade: 8.8 10.9 Nuts grade: 8 10 Washer hardness class: HV100, HV200, HV300 Thread size: M20-M72 Mechanical properties: : ISO898-1 8.8 10.9 Quality management systems:: ISO9001 -

DAST

General Requirement: EN 14399-1 Tolerance: 6ga International Standards: ISO 261, ISO 965-2 Property Class: 10.9 European Standard: EN ISO 898-1 -

CE bolt, EN14399 HV HR hexagon bolt for wind turbine generator

General require-ments: EN 14399-1 Bolt/nut assembly: EN 14399-3、EN 14399-4 Marking: HR、HV Property classes: 8.8/8、10.9/10、10.9/10 Quality management systems: ISO9001 -

DIN EN ISO 8765 GR.8.8 10.9 Hexagon head bolts with metric fine thread

It is applicable to anchor bolt components for the foundation of onshore and offshore wind turbines.

Alloy Hex head bolt with a hexagonal head and machined threads, functions in fastening 2 different parts with a nut, can be manufactured in alloy steel materials (42CrMo, 40CrNiMoA, 35CrMo, 20MnTiB) and into various sizes for specific uses, which is designed to be installed using a spanner. Hexagon bolts are also generally available in large sizesBolt Fasteners is a professional large size (M16-M80) high tensile hex head bolt manufacturer, we sell large size hex bolt for high precision, heavy-duty fastening application, widely used in structural and industrial industries, automotive to marine, coastal, and high-temperature environments. Our Hex Head are featured with high tensile strength, cost-effective and wear and tear-resistant, high temperature and low-temperature applications.Half-threaded hexagon bolts. 8.8, 10.9, and other high-grade hexagon head bolts can be provided, which are suitable for high-temperature environments, marine and coastal operations, and have high anti-corrosion performance.Chamfered end (CH in accordance with ISO 4753.Incomplete thread us2Pwhere Pis the fine pitch specified in Tables 1to 51emax=1nom-band1smn=em-5Pwhere Pis the coarse pitch in accordance with ISO 262.Shortest standard length determined with 5d for thread size 8 mm, 4,5d for 10 mm, 4d for 12 mm to 22 mm3.75d for 24mm to 60mm and rounded (if necessary) to the nearest standard length; shortest standard length1 nom= 220 mm for 64 mm.Greatest standard length 1nom ≤ 10d or 500 mm, whichever is the shorterMarking and labelling1.1 Marking on productMarking shall be:for steel fasteners, as specified in ISO 898-1;for stainless steel fasteners, as specified in ISO 3506-1.1.2 Labelling on package:Labelling on the package shall be in accordance with ISO 898-1 or ISO 3506-1shall include at least:the reference to this document i.e.ISO 8765the thread size and pitch, d x P, and the nominal length, l,the symbol of the property class for steel fastenersThe grade and symbol of the property class for stainless steel fasteners,the type of”Finish- Coating”,The manufacturer’s and/or distributor’s identification and/or name,the manufacturing lot number as specified in ISO 1891-4the quantity of pieces in the package. DesignationThe designation requirements as specified in ISO 8991 shall apply for all sizes, with:The symbol of the property class for steel fasteners, as specified in ISO 898-1The grade and symbol of the property class for stainless steel fasteners, as specified in ISO 3506-1.When no specific”Finish-Coating”is specified in the designation. fasteners are delivered in the “as processed” condition.

-

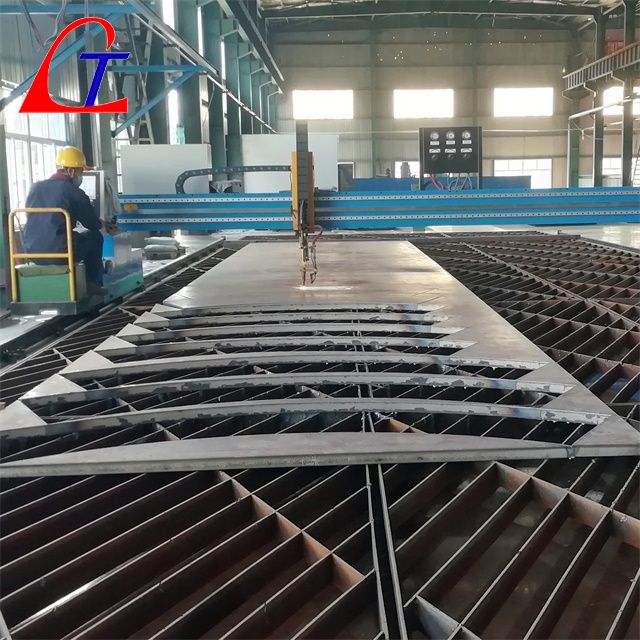

ANCHOR PLATE RING, FLANGE

6 steel plates are welded into a large ring and processed according to the requirements of the drawi

Material: q355c, q355d, q355ne, Q345E Weld flaw detection: class I in Nb / T 47013.3 Product thickness: 30-120, direct: no more than 5m Executive standard: processing according to the drawing -

Anchor Plate

Anchor PlateFoundation Anchor PlateWind Turbine Anchor Plate for foundation has 2 parts: upper and lower anchor plate(embed and template ring), which are connected by splice plates and high strength anchor bolts. Splice plate is a kind of rectangle plate which has the same mechanical properties of anchor plate, usually wind turbine foundation requires anchor plate with large diameter, compared with manufacture anchor ring plate in hot rolled method, use splice plate and seperate parts of anchor plate is more economical option.Anchor Plate Assembly Parts:There are many factors can influence the wind tower foundation configuration, wind turbine size and brand, site geotechnical conditions, etc. Wind tower cage foundation structure has to with stand compressive and uplift forces caused by strong wind forces. Before construction, investigation and research of structural and geotechnical design checks are needed.Anchor Plate Designed for Anchor CageThere are many factors can influence the wind tower foundation configuration, wind turbine size and brand, site geotechnical conditions, etc. Wind tower cage foundation structure has to with stand compressive and uplift forces caused by strong wind forces. Before construction, investigation and research of structural and geotechnical design checks are needed.This Drawing is designed for one of the many wind farm project.Anchor Plate Production ProcessAccording to the plan to buy steel plate (Q345E) → Rraw material re-inspection → Cutting (CNC programming, flame cutting) → Leveling → inspection → opening groove → cleaning and polishing → anchor plate group for tailor welding → inspection (100% ultrasonic flaw detection) → Cleaning Grinding → Appearance inspection → Leveling → Flatness Detection→ Machining → Inspection → CNC Drilling → Inspection → Sand blasting → Corrosion Protection Treatment → Inspection → Packaging → Storage.

-

Wind Turbine Blade Bushing

Application: To fix and cooperate with turbine blade root bolt Standard: clients’ requirements Material: 42CrMoA、40CrNiMo Property class: 8.8、10.9、12.9 Specification: M27-M64 Length: 100-900mm Coating: oil、black、dacromet 、zinc spray Advantage: High product performance, Impact energy up to 60J, high precision in dimension

OEM fabrication Heat-treated round bar Grinted steel rod Cold rolled thread Turning lathe

-

HEAT-TREATED ROUND BAR

The whole support rod body is in the black skin state after quenching and tempering

Material: 42CrMoA, 35CrMoA, 40CrNiMoA Product level: Class 8.8, Class 10.9, Class 12.9 Product specifications: Ф16~Ф100 Length: No more than 12m Executive standard: GB/T3098.1

-

Round Bar Heat Treatment

Heat treatment (Quenching + Tempering)Round bar heat treatment is quenching and high temperature tempering or hardening and tempering, is adopted to meet the mechanical properties of 8.8 and 10.9 grade anchor bolts (according to the requirements of the bidding technical documents).Quenching and tempering parts mostly work under relatively large dynamic loads. They are subjected to tension, compression, bending, torsion or shear. Some surfaces also have friction, requiring a certain degree of wear resistance and so on. In short, parts work under various complex stresses. These parts are mainly structural parts of various machines and mechanisms, such as shafts, connecting rods, bolts, gears, etc. They are widely used in machine tools, automobiles, tractors and other manufacturing industries. Especially for large parts in heavy machine manufacturing, quenching and high temperature tempering is more used. Because of the different stress conditions, the properties of conditioned parts in mechanical products are not exactly the same. Generally speaking, all kinds of quenched and tempered parts should have excellent comprehensive mechanical properties, that is, proper combination of high strength and high toughness, in order to ensure the long-term smooth work of parts. Round bar temperingQuenched round bar is reheated to a certain temperature and then cooled by a certain method, which is called tempering. Its purpose is to eliminate the internal stress produced by quenching, reduce the hardness and brittleness, and achieve the expected mechanical properties.The main purpose of quenching and high temperature tempering is to obtain comprehensive mechanical properties with good strength and plasticity. Our company has been engaged in heat treatment of round bar for many years. Welcome friends in need to establish cooperative relations with our company.

-

Round Bar CNC Machining

Best Quality with Best MachinesBolt Fasteners has been making efforts to upgrading manufacturing machines, various types of modern machines are adopted in the production line: external hexagonal chamfering machine, CNC machine, automatic hot forging machine and threading machine for making high accuracy and high-quality hex bolt, stud bolt, threaded rod or bar products. We can produce high accuracy customized products according to your drawing requirement.High Accuracy Machining EquipmentWith the help of these advanced machines we are able to provide our customers with better accuracies and finish with the help of CNC machines. These also help us in providing and accomplishing difficult tasks at much easier pace and with repeated and consistent manufacturing.Socked Hex Head ProcessingOne socket hex head bolt product supplied by Longteng is Wind Blade Root Bolt, customers can have socket hex head processing fabrication service on bolt, stud and rod products. Send Quotation now for more details about the fabricating process and equipments.Customize Samples for Customer

-

Round Bar Cold Threading

Thread rolling:Thread of round bar is made by thread rolling machine, and it is measured by thread micrometer and through stop gauge to ensure thread size and precision to meet the technical requirements.Thread rolling is the preferred method of producing strong, smooth, precise, uniform external threads. Rolling is different from other types of threading, such as cutting, grinding and chasing.Thread rolling is a cold forging process that can be performed on any ductile metal. This forming process can be used to produce other special shapes such as knurling. In order to obtain the best quality threads, the process is carried out on precision uncentered blanks. The blank diameter of the rolled thread is at the pitch diameter and is the theoretical point between the large diameter and the small diameter.The thread rolling company produces rolling threads for various parts. In general, rolling threads are required in the design due to the excellent tensile, shear and fatigue strength of the rolled threads. Other processes remove the material to create a thread form, but thread rolling replaces the material with a hardened steel mold. These molds typically have a hardness between Rc58-Rc63 and a specific set of dies for each thread size and each thread form.The material particles are moved into the shape of the thread instead of being weakened by removing the material, with the result that the particles become denser at key parts of the thread, especially on the sides below the root and the pitch. This effect improves the quality of the thread form. Excellent surface treatment improves the assembly between the internal and external threads and reduces the wear between the mating parts, thus extending their service life. Another advantage of the rolled threaded assembly is that the surface is smooth compared to other threaded components.

-

Round Bar Grinding

Grinding is such a significant process which gives final judgment to the tolerance, straightness, and precision of a round bar. This takes a thoroughly abrasive method of biting and cutting away unwanted bar parts from the material to improve the outer surface, finish and mill to the middle diameter, to ensure straightness, surface roughness and other requirements in line with the drawings.There are lots of reasons for the round bar needs grinding, mainly contains, accurate tolerance needed, precise straightness, finished smooth surface and abrasive material removal.Grinding methods have become popular and useful to most operators because they can perform all the necessary work under one roof – during fast delivery times. Rapid material removal enables high-precision work and brings out the physical properties required for steel bars.Grinding steel can be done in a variety of ways, depending on the type of workpiece that requires specific tolerances, cuts and diameters.

-

Round Bar Polishing

Round Bar PolishingPolishing:Round bar polishing is an important process of making a shiny and smooth surface of the finished products. Polishing main applies to precision machinery and optical industry and architectural applications or some other fields.The products after polishing have excellent reflect effect. Through polishing, the finished products can lower the risk of corrosion from oxidation and reduce contamination risks by eliminating cracks or crevices where bacteria and other harmful contaminants might gather. At the same time, it can improve the service life of round bar.Methods of polishingGenerally, the main methods are rubbing or using a chemical action. The purpose of polishing is to improve the surface smoothness and guarantee the steel bars’ out of roundness not more than 0.05mm, (rough≤3.0μm) of steel bars.

CLASSICS ALL OVER THE WORLD

PROJECT CASES

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →

Understand more →